Description

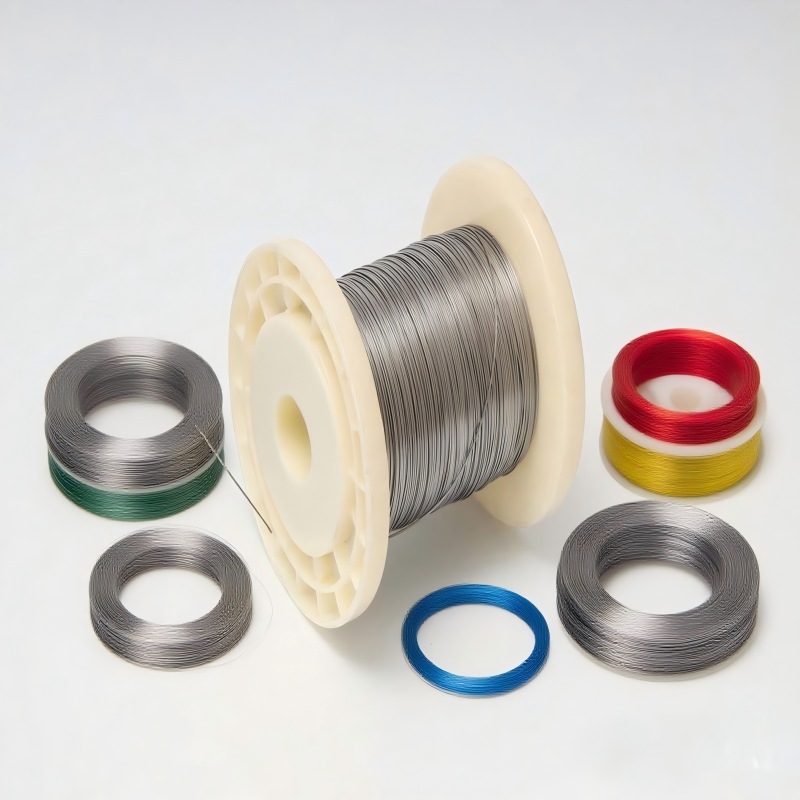

Nitinol Wire Description

Nitinol wire, a nickel-titanium (NiTi) alloy, stands out for its unique shape memory and superelastic properties. When deformed, it can return to its pre-set shape upon heating, making it invaluable in medical applications. Medical-grade Nitinol wire undergoes stringent processing to ensure high purity and biocompatibility. Manufacturers adjust its composition and treatment to achieve specific performance characteristics, such as transition temperatures and mechanical strength. This adaptability allows it to meet diverse clinical needs, from flexible guidewires to durable implants.

Nitinol Wire Applications in Healthcare

The medical industry relies heavily on Nitinol wire for minimally invasive procedures. Cardiovascular stents, for example, benefit from its ability to expand precisely within blood vessels. Orthodontists use NiTi alloy medical wire for braces due to its consistent force delivery and fatigue resistance. Additionally, surgical tools like biopsy forceps and retrieval baskets incorporate Nitinol for enhanced maneuverability. Emerging applications include neurovascular devices and robotic-assisted surgery instruments. Its compatibility with MRI and CT imaging further broadens its medical utility.

Comparative Analysis: Why Nitinol Outperforms Alternatives

Compared to stainless steel and titanium, Nitinol wire offers superior flexibility and fatigue resistance. Traditional metals may fail under repeated stress, whereas medical-grade Nitinol wire withstands millions of cycles without permanent deformation. Its corrosion resistance ensures long-term safety in bodily fluids. Furthermore, Nitinol’s ability to adapt to body temperature changes improves patient comfort and device reliability. These advantages make it the preferred material for life-saving implants and precision surgical instruments.

Custom Nitinol Wire Specifications for Medical Use

Manufacturers provide Nitinol wire in diameters ranging from microns to several millimeters, tailored to device requirements. Key specifications include transition temperature (Af), tensile strength, and surface finish. Some applications demand polished wire for reduced friction, while others require textured surfaces for better adhesion. Specialized coatings, such as PTFE or gold plating, enhance performance in specific environments. Clients can request custom heat treatments and mechanical testing to ensure compliance with medical standards like ASTM F2063.

Medical Device & Technology Markets

We Serve Our medical-grade Nitinol wire supports innovations across multiple healthcare sectors. In cardiology, it enables self-expanding stents and occlusion devices. Orthopedic applications include bone staples and spinal fixation systems. Dental professionals use it for archwires and root canal files. Beyond implants, Nitinol plays a crucial role in diagnostic tools, endoscopic instruments, and even wearable medical devices. Research institutions and biomedical startups also leverage our wire for prototyping next-generation medical technologies.

Contact Us for Premium Nitinol Wire Solutions

Looking for high-quality Nitinol wire for medical applications? Our team specializes in custom NiTi alloy solutions that meet FDA and ISO standards. We offer technical support, rapid prototyping, and bulk supply for large-scale production. Collaborate with us to create advanced medical devices with superior performance. Reach out to our specialists today for a consultation.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

| Product | Description |

| Nitinol Wire | High-performance shape memory wire |

| Nitinol Tube | Ultra-thin precision tubing |

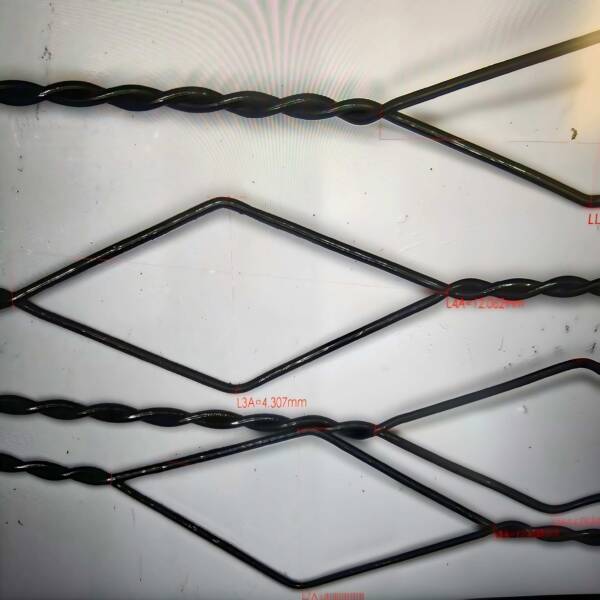

| Nitinol Rope | Flexible and durable for complex movement |

| Nitinol Guide Wire | Steerable wire for precise medical navigation |

Reviews

There are no reviews yet.