Description

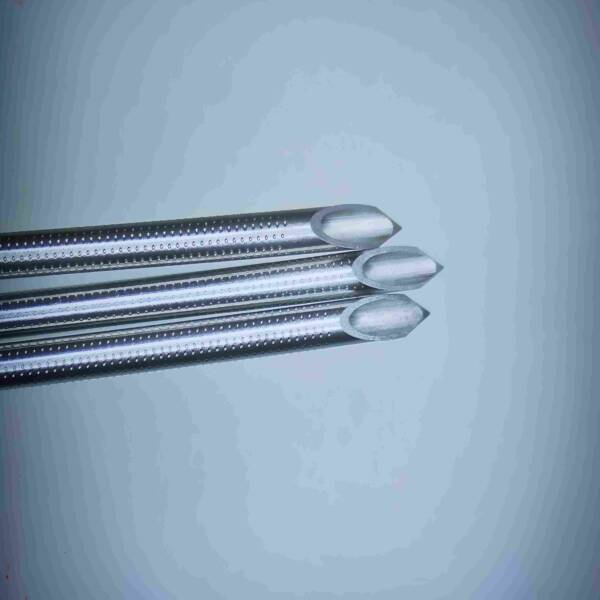

Superelastic Nitinol Tube | ASTM F2063 Medical Grade

We supply premium superelastic Nitinol tubes designed for medical applications, fully compliant with ASTM F2063 standards. These superelastic Nitinol tubes offer exceptional flexibility, fatigue resistance, and biocompatibility—making them a top choice for demanding medical device manufacturing.

Material Advantages of Superelastic Nitinol Tubes

Our medical-grade superelastic Nitinol tubes are crafted from a nickel-titanium alloy. This unique material delivers remarkable superelastic behavior, enabling significant deformation while recovering its original shape effortlessly. Additionally, it provides reliable shape memory performance and superior corrosion resistance—essential for safe and lasting use in medical environments.

Nitinol vs. Stainless Steel: Why Choose Our Tubes?

-

Furthermore, these tubes offer far greater fatigue life and durability

-

As a result, they are significantly more lightweight and flexible

-

Consequently, they demonstrate higher resistance to corrosion, even in bodily fluids

-

Moreover, they perform exceptionally well under repetitive stress conditions

Excellent Choice for Surgical Applications

Nitinol tubes are widely used across the medical field primarily because of their:

-

Outstanding biocompatibility

-

Full MRI compatibility

-

Ability to endure high strain without deformation

-

Furthermore, they offer versatility in devices like stents, guidewires, and orthodontic archwires

Addressing Common Nitinol Challenges

-

Although initial costs are higher than stainless steel, the longevity provides better value

-

Additionally, we employ specialized manufacturing techniques to ensure quality

-

Moreover, advanced surface treatments effectively minimize nickel release risks

Comprehensive Diameter Range

We offer an extensive selection of superelastic Nitinol tube sizes, including:

Guide Tube

| Nominal OD | OD Tolerances | ID Tolerances |

| OD ≤ 0.3mm | ±0.005mm | ±0.010mm |

| 0.3mm < OD ≤ 0.5mm | ±0.010mm | ±0.010mm |

| 0.5mm < OD ≤ 1.0mm | ±0.010mm | ±0.010mm |

| 1.0mm < OD ≤ 1.5mm | ±0.010mm | ±0.010mm |

| 1.5mm < OD ≤ 2.5mm | ±0.010mm | ±0.020mm |

| 2.5mm < OD ≤ 3.5mm | ±0.020mm | ±0.030mm |

| 3.5mm < OD ≤ 5.0mm | ±0.020mm | ±0.040mm |

| 5.0mm < OD ≤ 10.0mm | ±0.020mm | ±0.040mm |

| 10.0mm < OD | ±0.050mm | ±0.050mm |

Stent Tube

| Nominal OD | OD Tolerances | WT Tolerances |

| OD ≤ 0.3mm | ±0.010mm | ±0.010mm |

| 0.3mm < OD ≤ 0.6mm | ±0.015mm | ±0.015mm |

| 0.6mm < OD ≤ 1.5mm | ±0.020mm | ±0.015mm |

| 1.5mm < OD ≤ 2.5mm | ±0.020mm | ±0.020mm |

| 2.5mm < OD ≤ 3.5mm | ±0.020mm | ±0.020mm |

| 3.5mm < OD ≤ 5.0mm | ±0.030mm | ±0.030mm |

| 5.0mm < OD ≤ 10.0mm | ±0.050mm | ±0.030mm |

| 10.0mm < OD | ±0.050mm | ±0.050mm |

Diverse Medical Applications

-

Vascular and cardiovascular stents

-

Orthopedic implants and instruments

-

Minimally invasive surgical devices

-

Additionally, dental and orthodontic applications

Why Choose Our Superelastic Nitinol Tubes?

Our products are manufactured under strict quality control and meet all international medical standards. Consequently, we offer consistent performance, precise dimensions, and reliable delivery for medical device producers worldwide.

Contact us today to request a quote or discuss your custom requirements.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.