Description

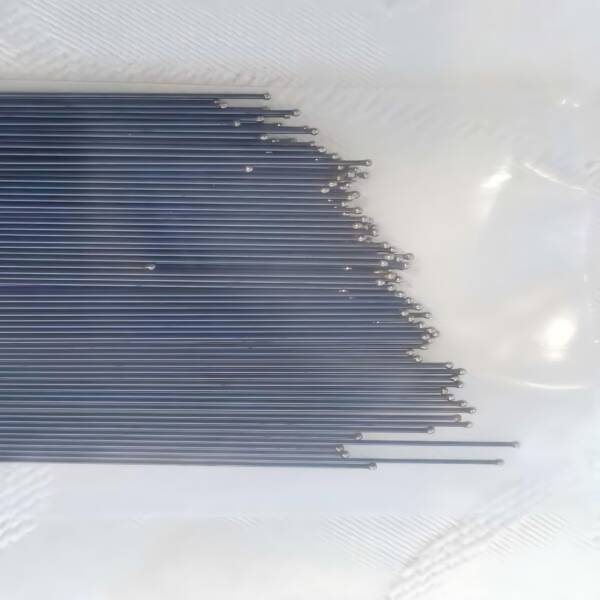

Nitinol Wire Description

Our company supplies premium Nitinol wire with exceptional shape memory and superelastic properties. This nickel-titanium alloy wire offers consistent performance in medical applications. We provide various diameters from 0.05mm to 2.0mm. All wires meet strict ASTM F2063 standards. Surface finishes include polished, etched, and sandblasted options.

Nitinol Wire Applications

Medical device manufacturers use our Nitinol wire for guidewires, stents, and orthodontic archwires. The aerospace industry applies it in actuators and couplings. Robotics engineers value its fatigue resistance for flexible components. Our wires also suit industrial sensors and automotive safety systems.

Comparative Analysis

Our Nitinol wire outperforms stainless steel in flexibility and strain recovery. It maintains better corrosion resistance than cobalt-chromium alloys. Compared to polymer alternatives, it offers superior strength and temperature stability. These advantages make it ideal for demanding medical environments.

Medical Device & Technology Markets

We Serve We supply Nitinol wire to cardiovascular device producers and orthopedic implant manufacturers. Dental equipment companies use our wires for precision tools. Research institutions rely on our materials for prototype development. Our global distribution network serves clients in North America, Europe, and Asia.

Why Choose Our Nitinol Wire?

We maintain ISO 13485 certification for quality management. Our production facility features advanced wire drawing technology. Batch testing ensures consistent mechanical properties. Custom alloys are available for specific transition temperatures. Technical support includes material selection guidance.

Contact Us

Request a quote today for medical-grade Nitinol wire. Our sales team responds within 24 hours. We offer samples for material evaluation. Volume discounts apply for large orders. Let’s discuss your project requirements.

Reviews

There are no reviews yet.