Description

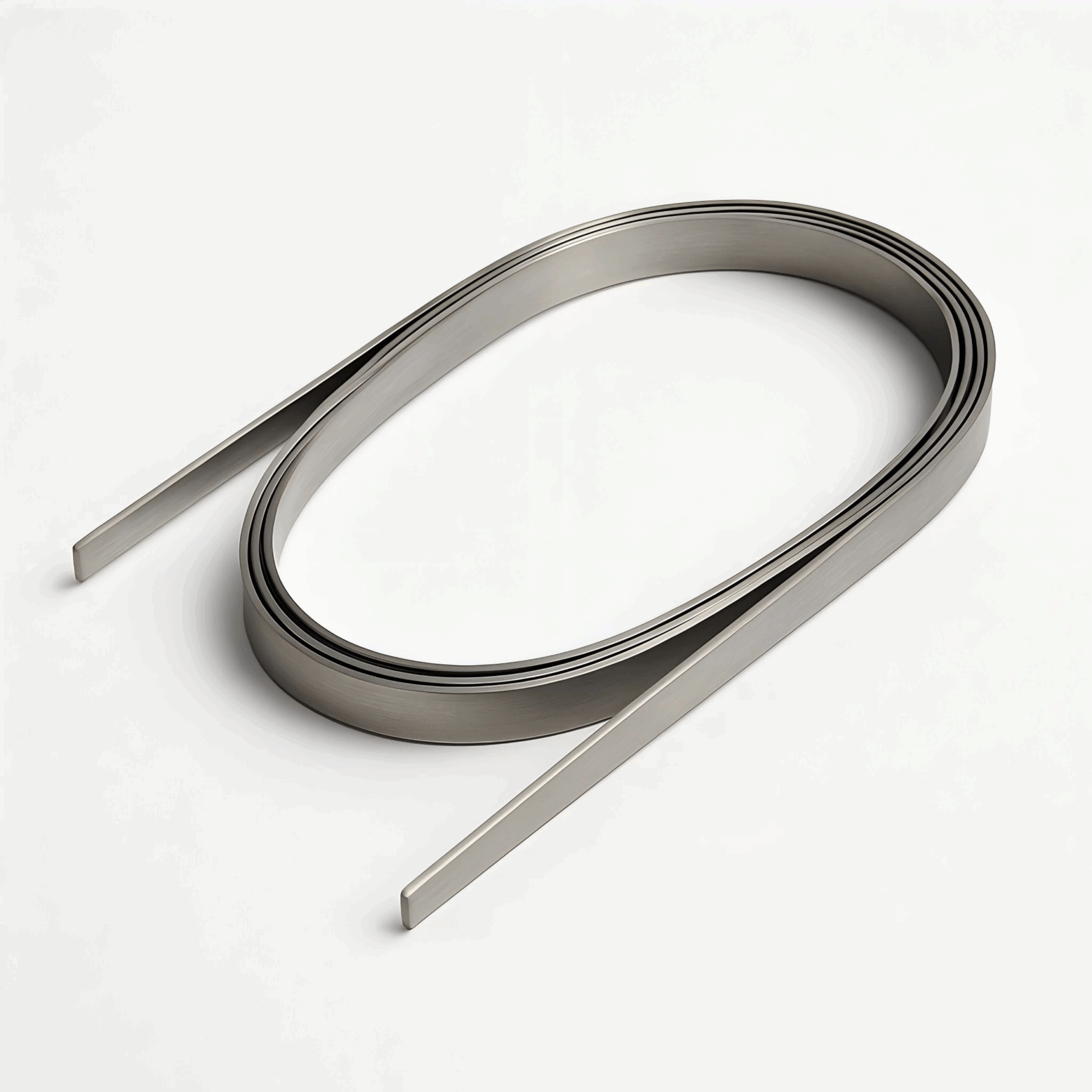

Nickel Titanium Flat Wire – Superelastic Precision for Implantable Devices

Our nickel titanium flat wire is engineered from high-purity Nitinol (Nickel-Titanium Naval Ordnance Laboratory alloy), typically containing 55–56% Nickel and 44–45% Titanium. This specific ratio is carefully controlled to deliver the material’s extraordinary Shape Memory Effect (SME) and Superelasticity, making it ideal for demanding medical and industrial applications.

What Is Nitinol?

Nitinol is a smart alloy with the remarkable ability to “remember” and return to a pre-set shape when heated above its Austenite Finish (Af) temperature. At cooler temperatures, it exists in a flexible Martensite phase, which transforms into a rigid Austenite phase when heated—enabling the shape memory behavior. It also offers instant recovery after significant deformation, thanks to its superelastic phase transformation.

Medical-Grade Material for Critical Applications

We specialize in medical-grade nickel titanium flat wire manufactured to meet ASTM F2063 biocompatibility standards. With superior fatigue resistance, MRI compatibility, and exceptional flexibility, it is ideal for:

-

Orthodontic archwires

-

Stents and vascular implants

-

Guidewires and catheter reinforcement

-

Orthopedic fixation devices

-

Minimally invasive surgical tools

It’s also highly suitable for industrial uses requiring tight bending, repeatable motion, and corrosion resistance—such as actuators, sensors, or micro-mechanisms.

Key Features

-

Material: Premium medical-grade Nitinol (NiTi)

-

Core Properties: Shape Memory & Superelasticity

-

Function: Recovers its programmed flat shape upon heating or stress release

-

Surface Finishes: Etched, mechanically polished, or electropolished to reduce thrombogenicity and improve smoothness

-

Customizable Af Temperature: From sub-30 to 100+°C to fit your design needs

Why Choose Nickel Titanium Over Stainless Steel?

Compared to stainless steel, nickel titanium flat wire offers unmatched kink resistance, fatigue durability, and flexibility—especially in dynamic environments. While stainless steel may offer greater static tensile strength, it cannot match Nitinol’s ability to deform and recover repeatedly without permanent damage.

Precision. Reliability. Customization.

We maintain tight dimensional tolerances on width, thickness, and flatness, ensuring consistent performance. Whether you need custom lengths, specific Af temperatures, or specialized surface finishes, we deliver precision-engineered wire for critical applications.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Nitinol Wire – Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube – Precision-engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.