Description

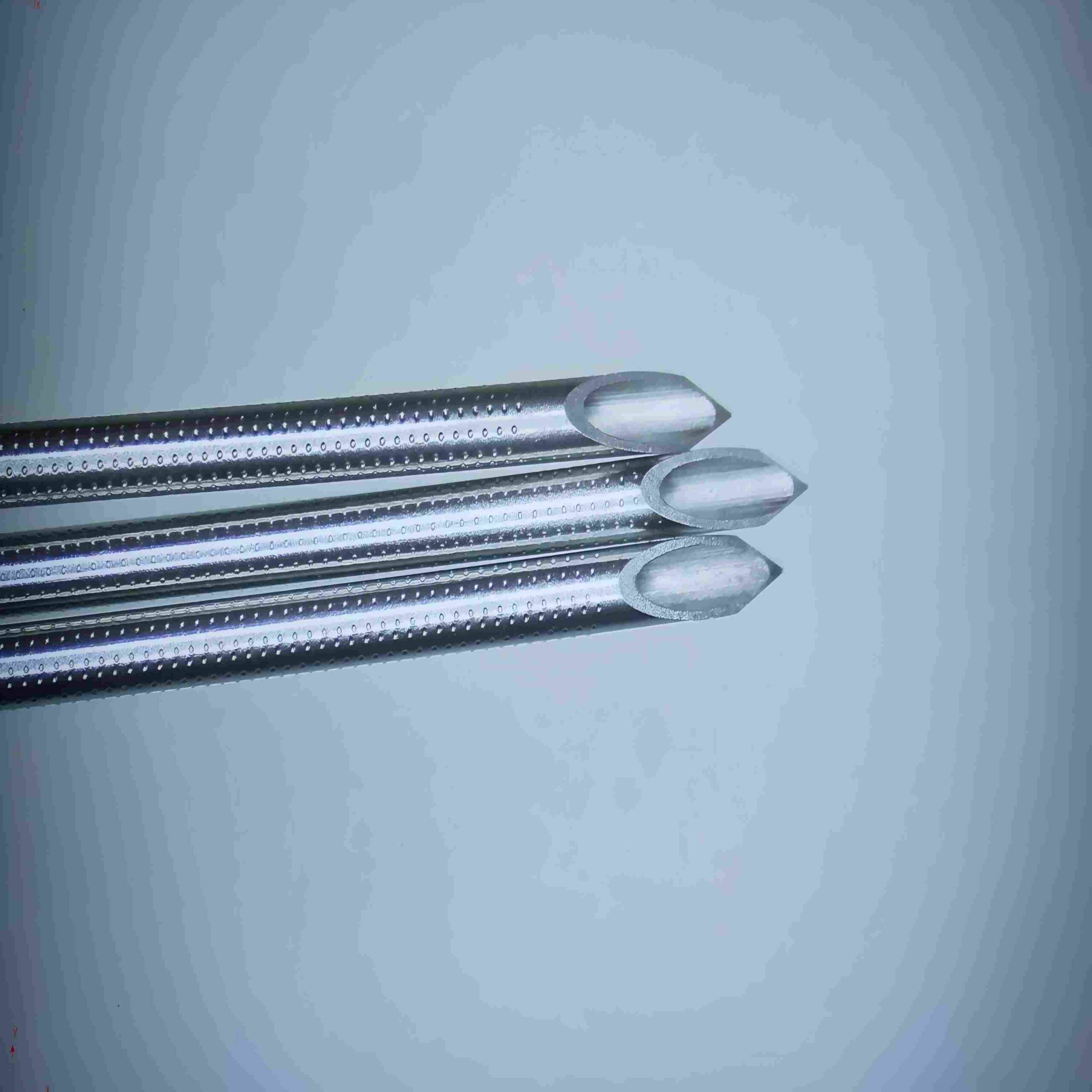

Nitinol Hypotubes for Medical Industry Use

Revolutionizing Medical Devices with Advanced Nitinol Tube Technology

Our factory specializes in producing high-quality Nitinol hypotubes for the medical industry. We use premium Nitinol material, a nearly equal atomic ratio of nickel and titanium (typically 54.5-57% nickel, balance titanium per ASTM F2063). This unique composition provides exceptional properties like superelasticity and shape memory effects, making it ideal for medical applications.

Nitinol hypotubes offer incredible flexibility and kink resistance. They can withstand repeated bending and stretching without permanent deformation, which is crucial for navigating complex human anatomy. Their mechanical behavior closely mimics natural tissues like bone and tendon, promoting better integration and healing.

Addressing Nitinol’s Challenges in Medical Applications

Nickel Ion Release: A primary concern with Nitinol is the potential release of nickel ions into the body. Nickel is a known allergen and carcinogen. We mitigate this risk through advanced surface treatments like electropolishing and passivation. These processes enhance the protective titanium oxide layer on the surface, reducing nickel release and improving biocompatibility.

Fatigue Crack Growth: Nitinol exhibits lower fatigue crack growth resistance compared to some other implant materials like stainless steel or cobalt-chromium alloys. Our precise laser cutting and strict quality control minimize surface defects that could initiate cracks, ensuring product longevity and reliability.

Manufacturing Difficulties: Nitinol is challenging to process due to phase transformations and work hardening. Our expertise in Nitinol tube development processing allows us to maintain tight compositional control (within ±0.05%) for consistent transformation temperatures. We employ specialized techniques like vacuum arc melting and careful thermomechanical processing to produce seamless, high-performance hypotubes.

Safety in Handling Nitinol Hypotubes

Is Nitinol safe to touch? Yes, handling Nitinol hypotubes is generally safe. The stable surface oxide layer provides a barrier against nickel release. For prolonged handling or those with nickel sensitivities, we recommend wearing nitrile gloves (like SafeTouch® Advanced™ or Touch NTuff). These gloves offer chemical protection and prevent potential irritation, ensuring operator safety during assembly and implantation procedures.

Precision Diameter Range for Diverse Applications

Our Nitinol hypotubes come in a wide range of diameters and wall thicknesses to meet various medical device needs:

-

Ultra-small hypotubes: As fine as 0.33mm outside diameter with 0.045mm wall thickness.

-

Common medical sizes: Include OD 1.5mm (ID 0.9mm), OD 2.0mm (ID 1.4mm), OD 2.5mm (ID 1.9mm), OD 3.0mm (ID 2.4mm), OD 3.5mm (ID 2.9mm), and OD 4.0mm (ID 3.4mm).

We maintain extremely tight tolerances and excellent surface finish (Ra ≤ 0.2μm) to minimize vascular damage and ensure smooth device operation.

Advanced Processing and Surface Treatments

Our Nitinol tube development processing involves state-of-the-art techniques. We optimize the alloy’s microstructure through controlled drawing and heat treatment processes. Advanced surface treatments like magneto-electropolishing (MEP) create a more corrosion-resistant surface with reduced nickel content, enhancing biocompatibility and hemocompatibility for blood-contacting devices like stents and vascular implants.

Commitment to Quality and Innovation

We adhere to strict medical industry standards (ASTM F2063) for composition and purity. Our hypotubes are manufactured in a controlled environment to minimize inclusions and defects. We continuously invest in research and development, exploring innovations like 3D printing and AI-driven design to further improve the performance and functionality of our Nitinol hypotubes for the future of minimally invasive medicine.

Explore our catalog today. Discover how our reliable Nitinol hypotubes can enhance your next medical device innovation. Contact us for custom specifications and expert technical support.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.