Description

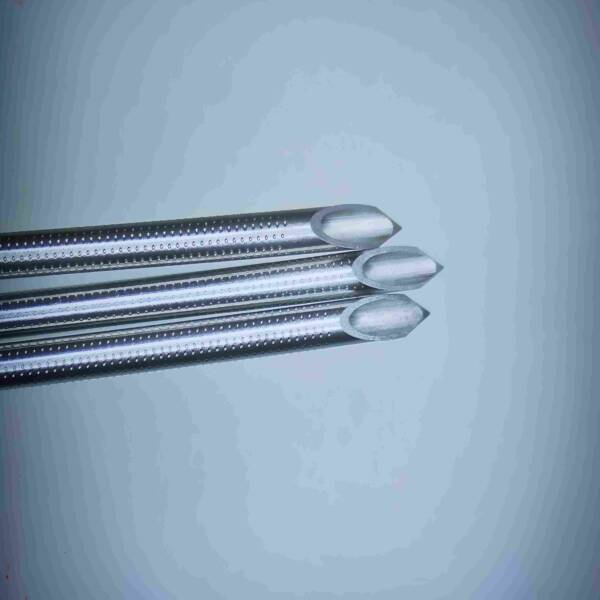

Precision-Cut Nitinol Hypotubes for Medical Devices

Get top-quality nitinol hypotubes laser-cut for critical medical applications. Our advanced laser cutting technology ensures every tube is accurate, burr-free, and ready for performance.

What is Nitinol?

Nitinol naturally switches between two phases: Martensite, which is soft and flexible at lower temperatures, and Austenite, which becomes firm and structured when heated. By setting its shape during production, we allow the material to “remember” that form. When cooled, it bends easily. When warmed again, it snaps back—this is the remarkable Shape Memory Effect.

How Does Nitinol “Remember” Its Shape?

Nitinol changes its internal structure based on temperature. At lower temperatures, it enters the Martensite phase, becoming soft and highly flexible. When heated, it transforms into the Austenite phase, regaining a firm, stable shape. During manufacturing, we program its desired geometry in the Austenite phase. Once cooled, the material can be deformed easily—but with heat, it rapidly returns to its original form.

Our Nitinol Hypotube Material

We use premium medical-grade nitinol hypotube stock that meets rigorous quality standards. Features include:

-

Superelasticity – Ideal for tight spaces like blood vessels

-

Biocompatibility – Safe for long-term implantation

-

High Strength-to-Weight Ratio – Delivers more strength per gram compared to stainless steel

-

Kink Resistance – Maintains lumen integrity under bending

-

Fatigue Resistance – Handles millions of flexing cycles

Key Applications for Laser-Cut Nitinol Hypotubes

Our laser-cut nitinol hypotubes are essential for:

-

Catheters – Steerable shafts for diagnostics or treatments

-

Stent Delivery Systems – Precise transport and deployment

-

Guidewires – Navigate complex anatomy safely

-

Minimally Invasive Tools – Flexible yet strong instrument components

-

Neurovascular Devices – Operate safely in delicate brain vessels

-

EP Catheters – For mapping and ablating cardiac arrhythmias

Why Use Laser Cutting for Nitinol Hypotubes?

Laser cutting is the industry gold standard for nitinol tubing:

-

Precision Cutting – Ideal for micro-patterns and fine details

-

Minimal Heat Affected Zone – Preserves shape memory properties

-

Smooth Edges – Burr-free, no extra finishing needed

-

Repeatability – High-volume consistency and accuracy

-

Delicate Wall Handling – Cuts ultra-thin walls without deformation

Nitinol Hypotube vs. Stainless Steel: What’s Better?

| Property | Nitinol Hypotube | Stainless Steel |

|---|---|---|

| Flexibility | Superior | Rigid |

| Kink Resistance | Excellent | Moderate |

| Shape Memory | Yes | No |

| Fatigue Life | Longer | Shorter |

| Cost | Higher | Lower |

Choose nitinol hypotube when flexibility, fatigue life, and performance matter most—especially for dynamic, complex environments inside the body.

Why Choose Us?

We specialize in medical nitinol hypotube manufacturing. Our advantages:

-

Deep material expertise

-

State-of-the-art laser systems

-

ISO-13485 certified quality control

-

Traceable documentation

-

Collaborative engineering support

Let’s Talk

Get precision nitinol hypotubes tailored to your device.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Nitinol Wire – Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube – Precision-engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.